1. The gas flow rate should be set accurately when the furnace is installed. If it needs to be re-adjusted, follow the steps below:

2. Ensure the furnace door is closed.

3. Open the Status Panel of the furnace and enable “Manual Control”. See Manual Control Using the Status Panel.

4. Check that the ball valve is in the Open Position as indicated on the Status Panel. If not, press Open and ensure Close is not checked, and wait about 20s.

5. Turn on vacuum pump by pressing Vacuum relay

6. The vacuum pressure should drop below 10 Torr. View the pressure in the status panel.

7. Ensure that the valve at the top of the bottle of compressed gas is open.

8. Turn the Argon relay on using the Status Panel.

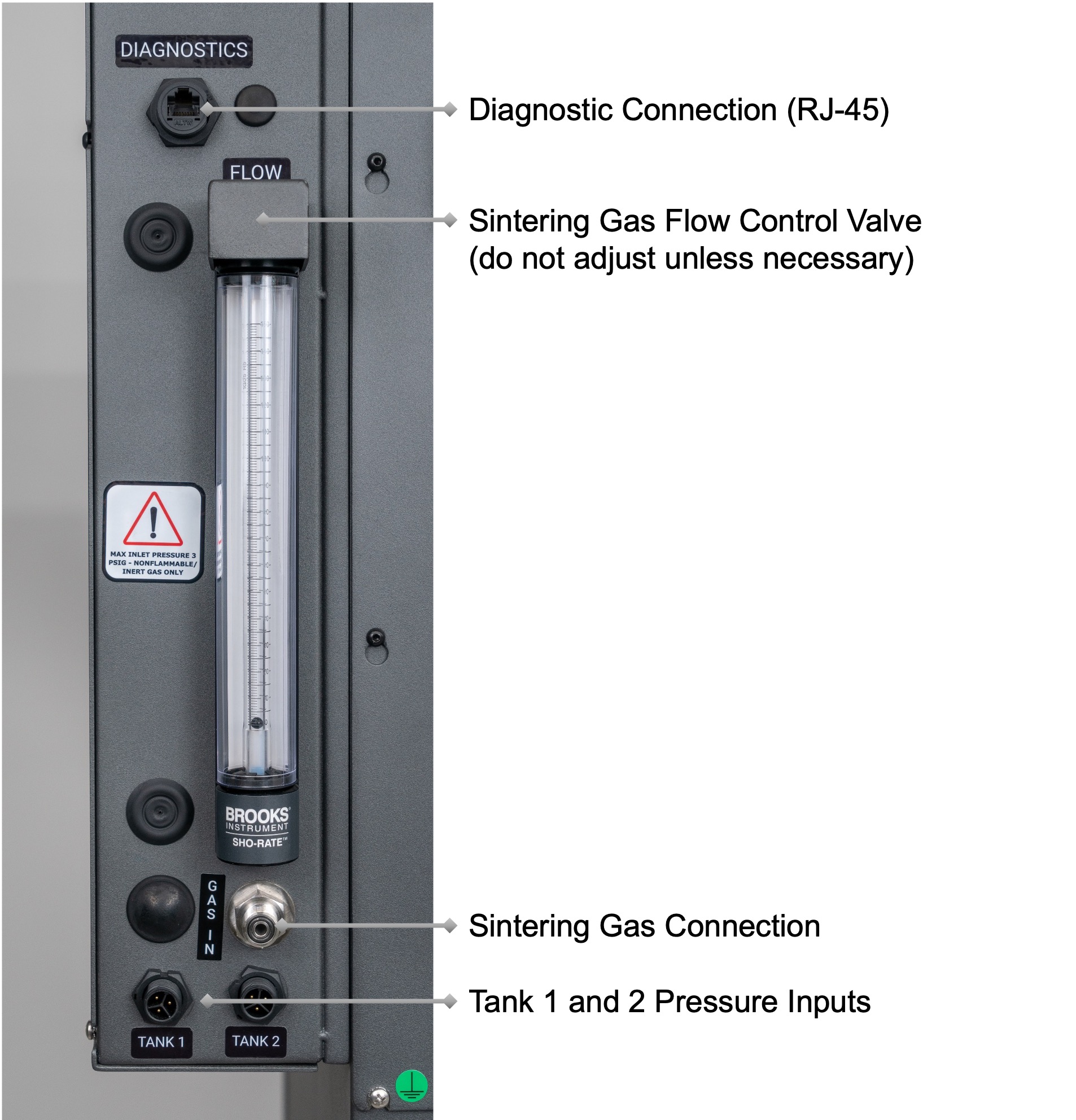

9. Wait and check the flow rate. It should be approximately 42 mm on the mm scale of the rotameter. For the location of the rotameter, refer to: The back panel.

10. Also check the pressure at the regulator. The pressure should be roughly 3 psi.

11. Turn the adjustment knob on the regulator up until roughly 3psi

12. Turn the rotameter adjustment knob to achieve flow of 42 on the mm scale.

13. Readjust the regulated pressure to be 3 psi using the adjustment knob.

14. Verify the flow rate, repeating steps 12 and 13 above until you reach the correct values.

15. Once done:

- Turn off argon on screen

- Turn off the vacuum relay.