Our growing materials portfolio includes several metals as well as an evaporative support material to unlock impossible part geometry and eliminate the need for support removal processes. Below you can find linked Datasheets and default settings we use in our Rapidia Cura and Rapidia Print Software.

¶ Material Feedstocks

| Metal | Status | Datasheet | Shelf Life | Notes |

| 316L Stainless Steel | Available | Datasheet | 12 months + | 3rd Party Qualified |

| 17-4 PH Stainless Steel | Available | Datasheet | 6 months + | 3rd Party Qualified |

| IN625 Nickel Superalloy | Available | Datasheet | 6 months + | |

| Pure Copper | Beta Release | 2 months + | ||

| Cemented Tungsten Carbide | In Development | |||

| H13 Tool Steel | In Development | |||

| D2 Tool Steel | In Development | |||

| Evaporative Support | Available | 12 months + |

¶ Evaporative Support Material

|

|

|

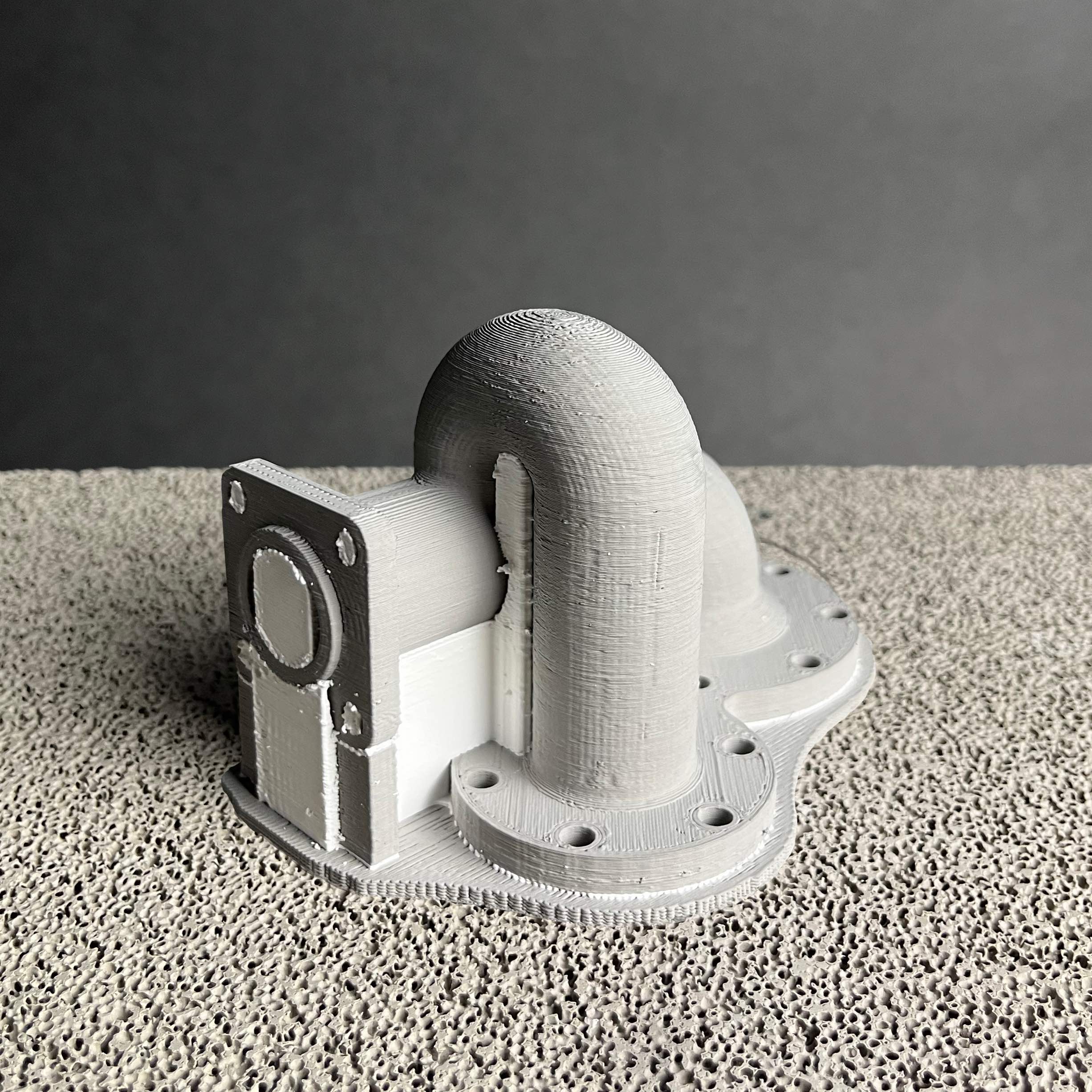

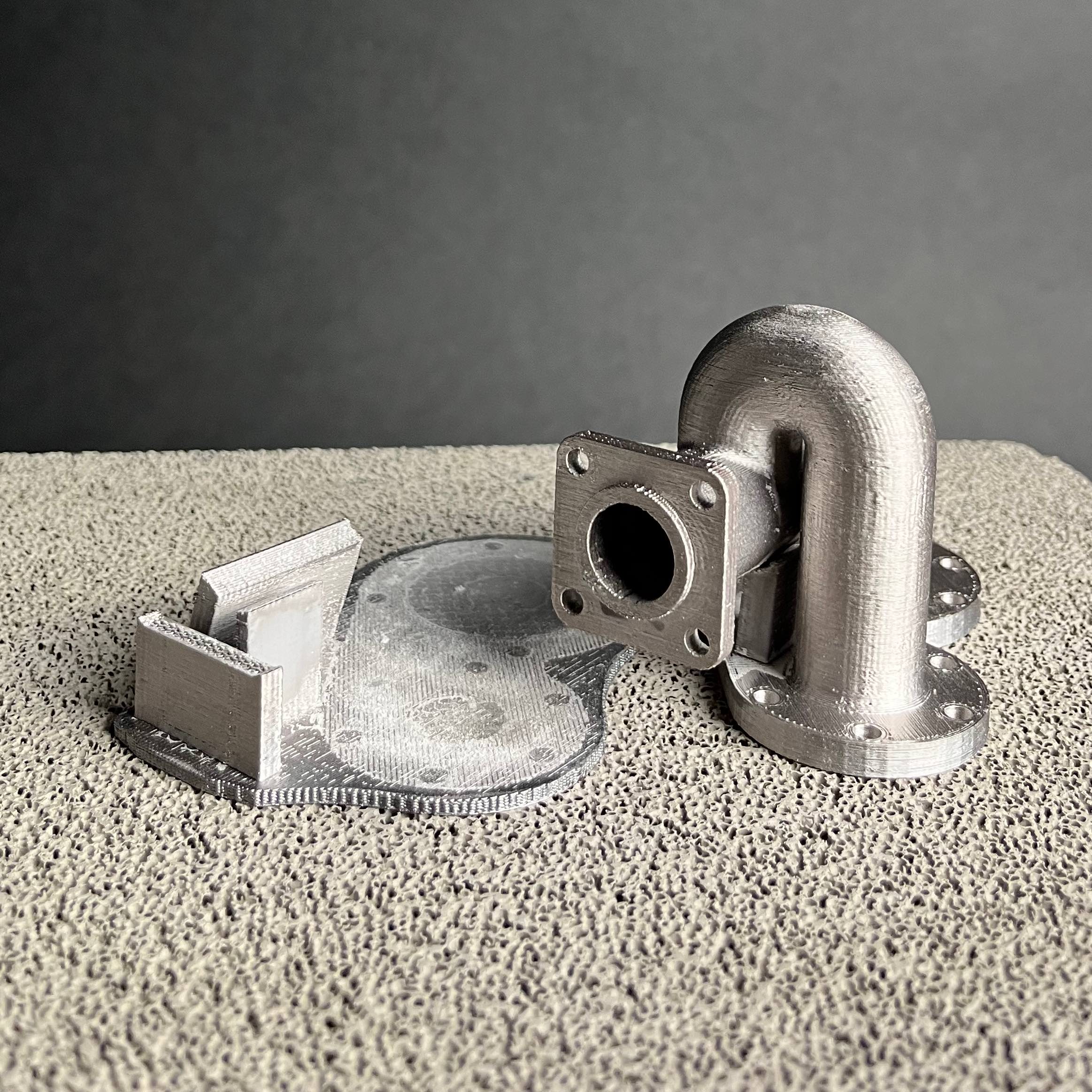

Design Freedom - Allows printing of any overhang. MPD can print overhangs up to 45° without printed support. Using evaporative support in the second extruder allows any overhang, including completely horizontal overhangs, to be printed. |

Easy Removal - Functions as a release layer between metal surfaces. Metal supports prevent sagging during sintering. A layer of evaporative material between the supports and the part enables easy removal. |

¶ Cartridges and Storage

Feedstock cartridges can be stored at any fill level and should be kept in a cool and dry place, ideally between 5-20°C (41-68F). Stainless steel feedstock containers are reused through our cartridge exchange program. Contact support@rapidia.com for further information.

Rapidia guarantees all of our materials for the shelf lives listed above, as calculated from the ship date.

¶ Default Settings

In Rapidia Cura and Rapidia Print Software

| Material | Density | Diameter | Cost per cc | Build Plate Temp. | Retraction Distance | Retraction Speed | Fan Speed | Flowrate Constant | Scaling Factor |

| 316L Stainless Steel | 4.6 g/cm3 | 0.64mm | ~0.40 USD/cc | 40°C | 1mm | 25 mm/s | 100% | 3.58g/2000mm | 116 |

| 17-4 PH Stainless Steel | 4.6 g/cm3 | 0.64mm | ~0.40 USD/cc | 40°C | 1mm | 25 mm/s | 100% | 3.58g/2000mm | 115.15; 115.37 |

| IN625 Nickel Superalloy | 4.6 g/cm3 | 0.64mm | ~1.00 USD/cc | 40°C | 1mm | 25 mm/s | 100% | 3.85g/2000mm | 132 |

| Evaporative Support Material | 1 g/cm3 | 0.64mm | ~0.20 USD/cc | 40°C | 1mm | 25 mm/s | 100% | 0.83g/2000mm | 116 |