The composition of Rapidia’s feedstock makes it possible to use a small amount of water to bond two printed parts together before sintering. The goal when green bonding is to bring the metal particles on each part’s surface into close enough proximity that they sinter together, creating a continuous part. The quality of the bond depends on the quality of the mate between the two bonding surfaces, even application of water, and firm clamping of the joint. While in theory a completely continuous part could be made, in practice the joint may not be as strong as the same part printed as a single piece because small bubbles and surface irregularities will result in some loss of contact between the two pieces. The following method can be used to water bond parts together.

¶ How To

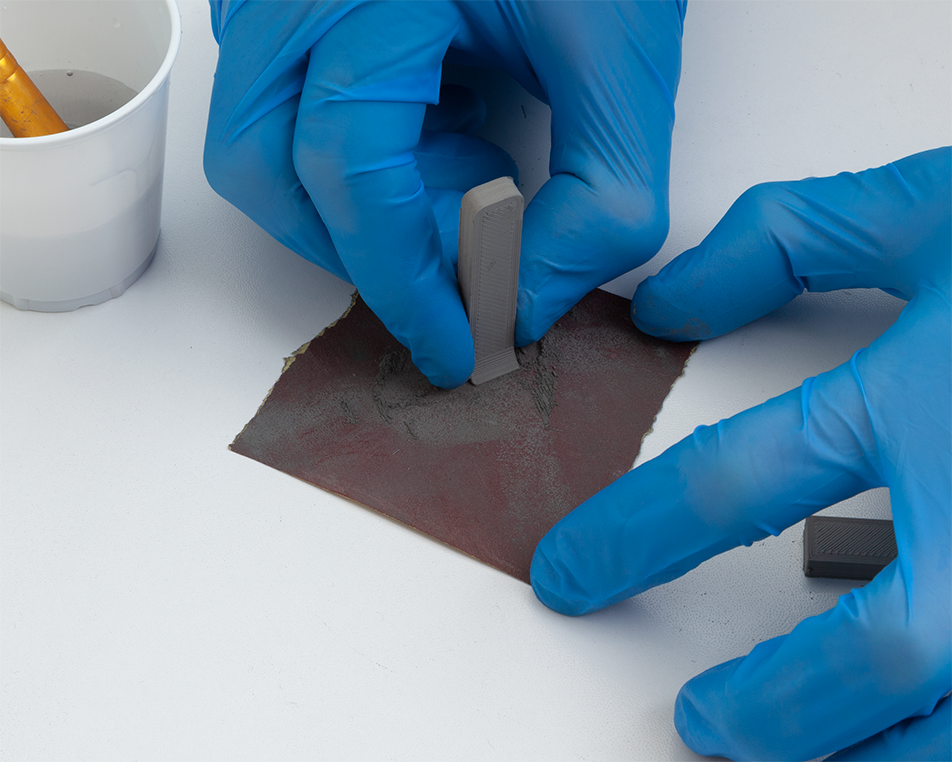

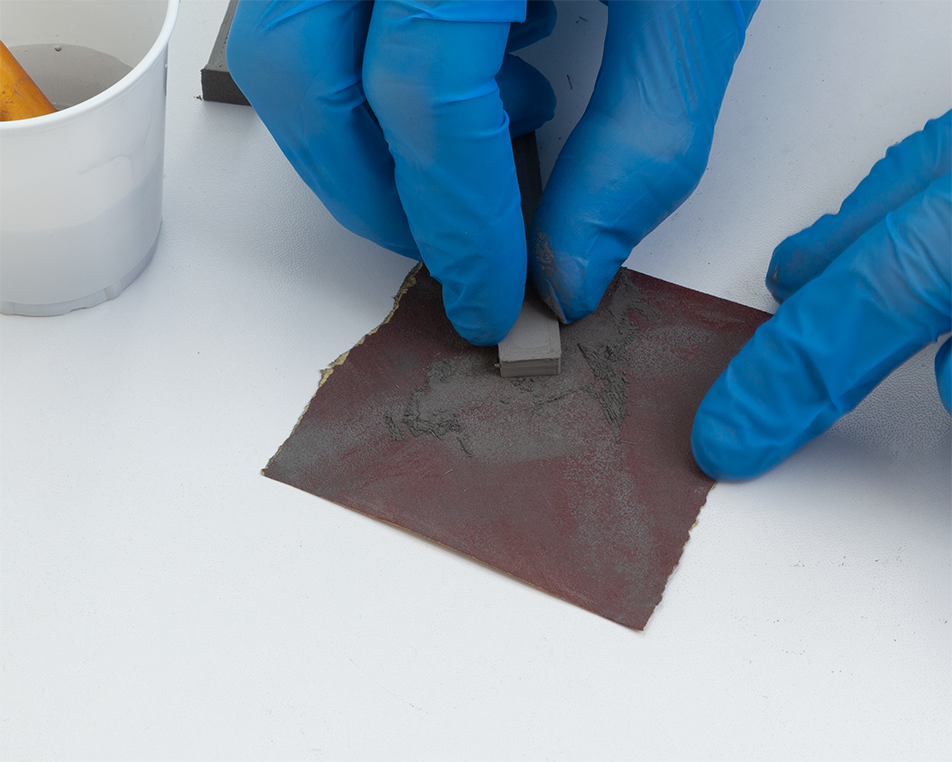

1. Use fine-grit sandpaper to smooth and flatten the parts where they will be bonded.

|

|

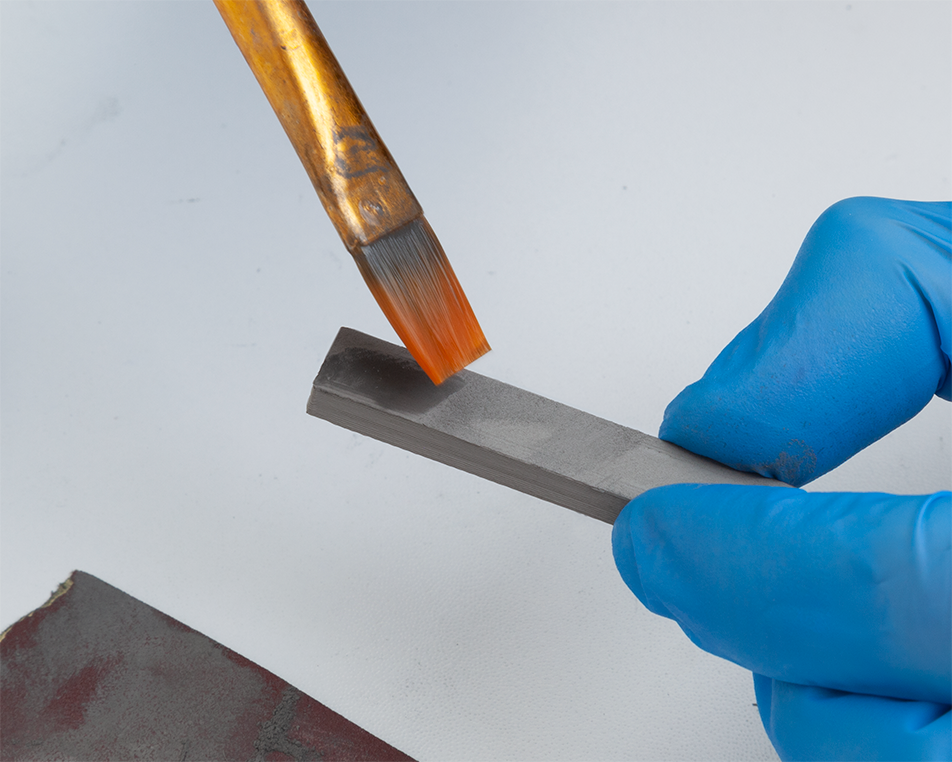

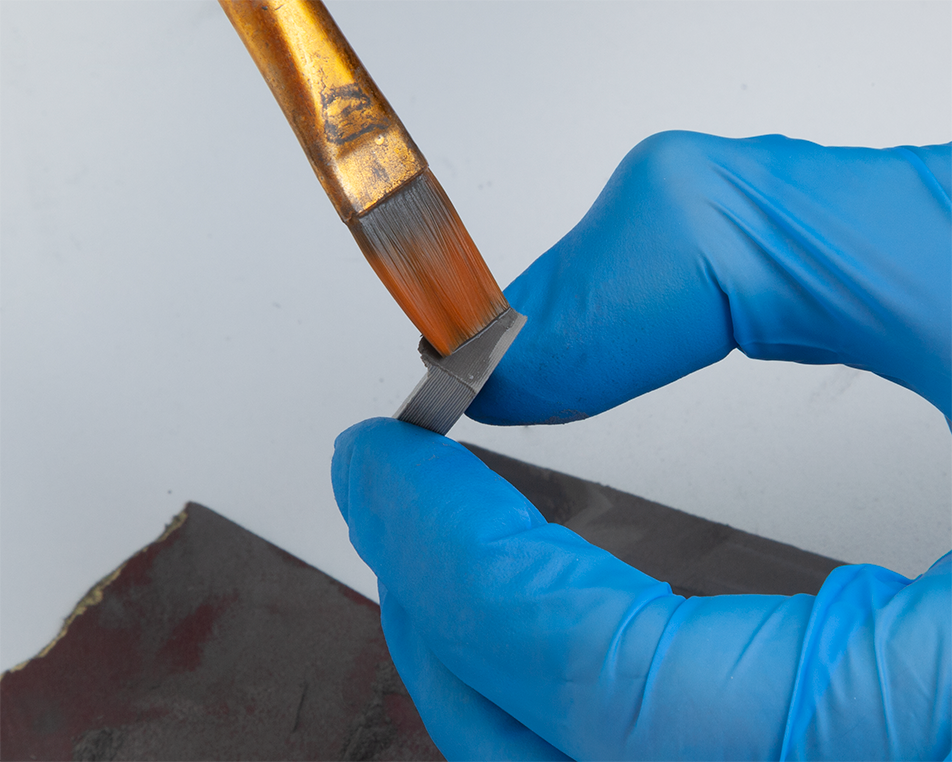

2. Using a brush, apply water to both parts where they will meet. Use water sparingly, applying only a thin film on each part. Too much will soften the surrounding material.

|

|

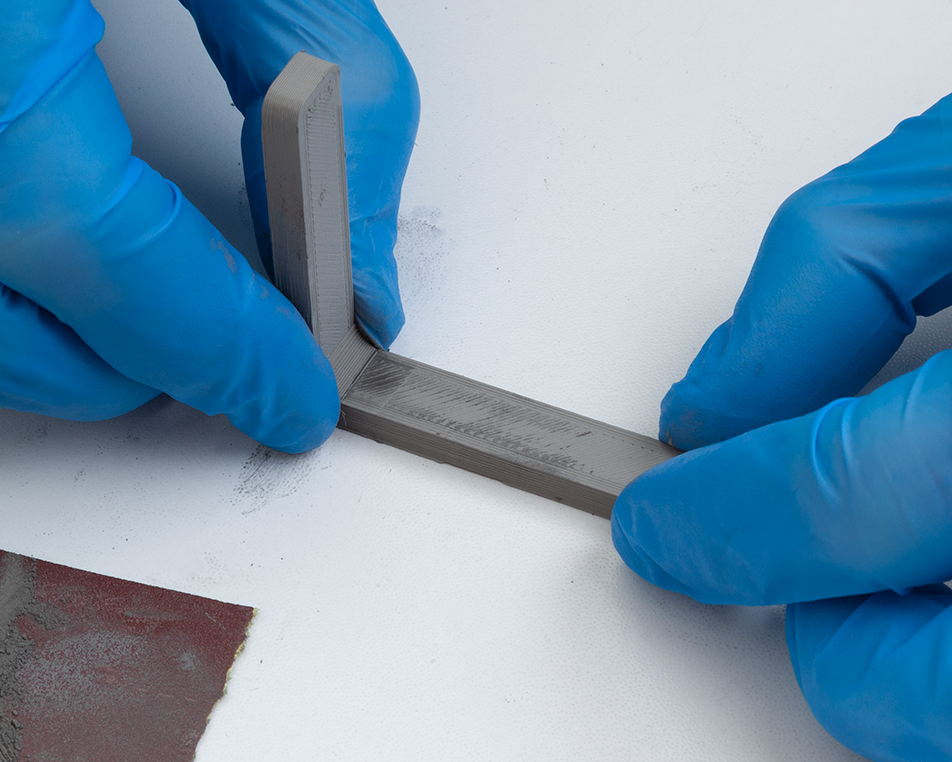

3. Apply firm pressure to the joint for ten seconds, ensuring that they are correctly aligned in the desired position. The joint will be weak until the water dries, so the part will need to be supported if the pieces don’t naturally stay together under their own weight.

4. Drying time varies based on the area being bonded, but will be on the order of a few hours at room temperature. The drying can be accelerated by placing the part in a small oven at 60-80C. When dry, the part is ready to be sintered.