The Conflux 1 Metal 3D Printing Platform uses a two-step process to create metal printed parts: First, the Conflux 1 Printer deposits metal paste, layer by layer, to build up a part. Next, the part, which is composed of metal powder held together by a small amount of polymer, is sintered to full strength in the Conflux 1 Furnace. To allow for a greater range of parts to be printed, the system also prints a support material, which temporarily supports regions of the metal as it is built up, but which evaporates during the sintering process. To use the system effectively, and to design parts appropriately for the process, it is helpful to understand the material’s transformation from feedstock to finished part:

¶ Printing with Metal Paste Deposition

Deposition:

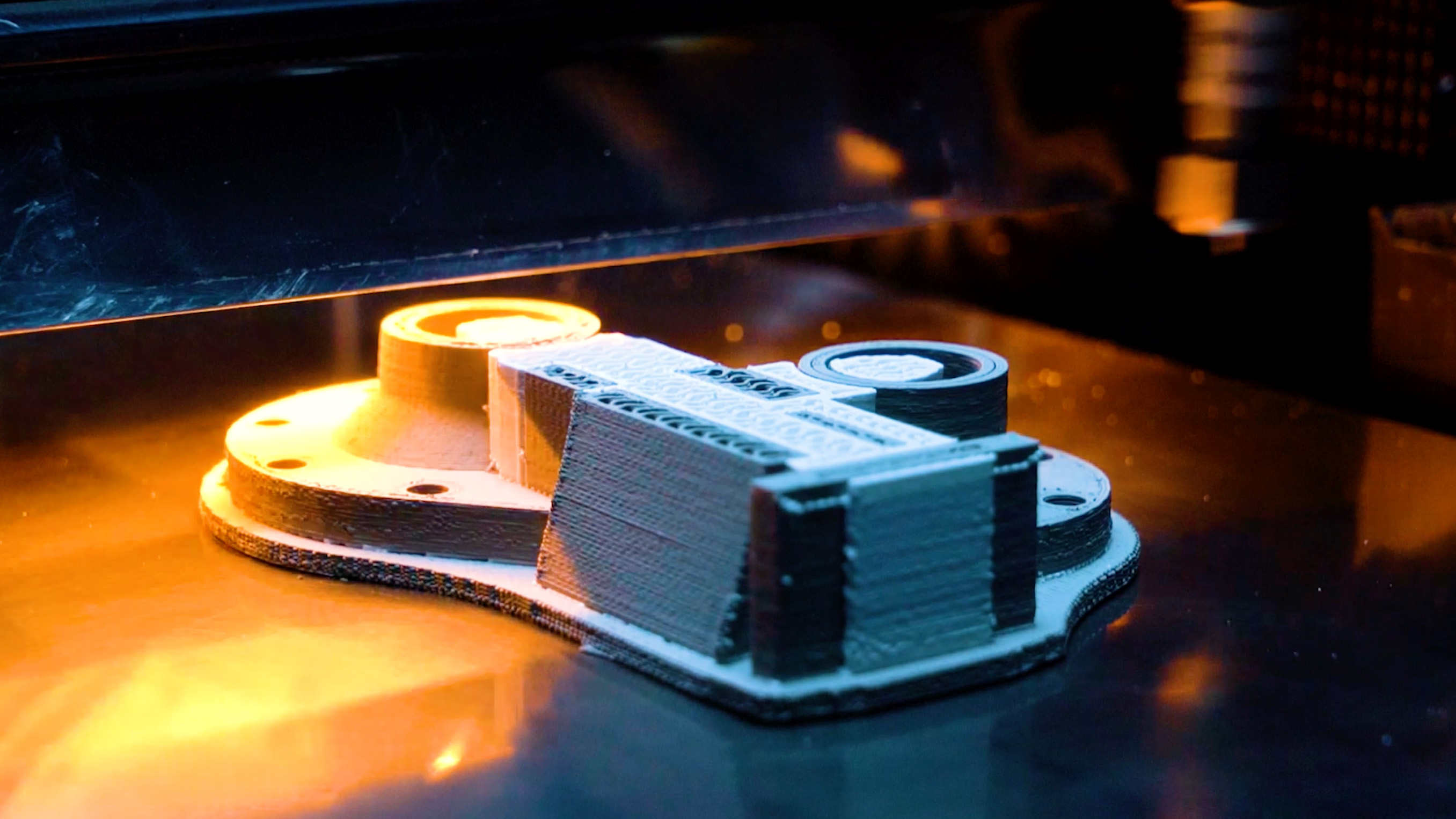

Both metal and support pastes are delivered as viscous (thick), and sticky pastes. In this condition the system is able to pump them from their cartridge, and extrude the materials accurately onto the printer’s build plate. Though their consistency is similar, the metal paste is dense and grey, and the support paste is lighter and white.

Drying:

As the materials are extruded into a shape on the build plate, they are dried both by the heated print bed, and a heat lamp. Drying causes both materials to harden, which allows the printed part to hold its shape prior to sintering. In the dry state, both materials are solid and are no longer sticky, but remain brittle, composed of particles held together only by the small amount of polymer left behind when the water evaporates. The metal paste has a similar strength and appearance to dry, unfired clay. The dry support material, on the other hand, is somewhat compressible (springy), and feels similar to a weak Styrofoam.

Sintering (high temperature):

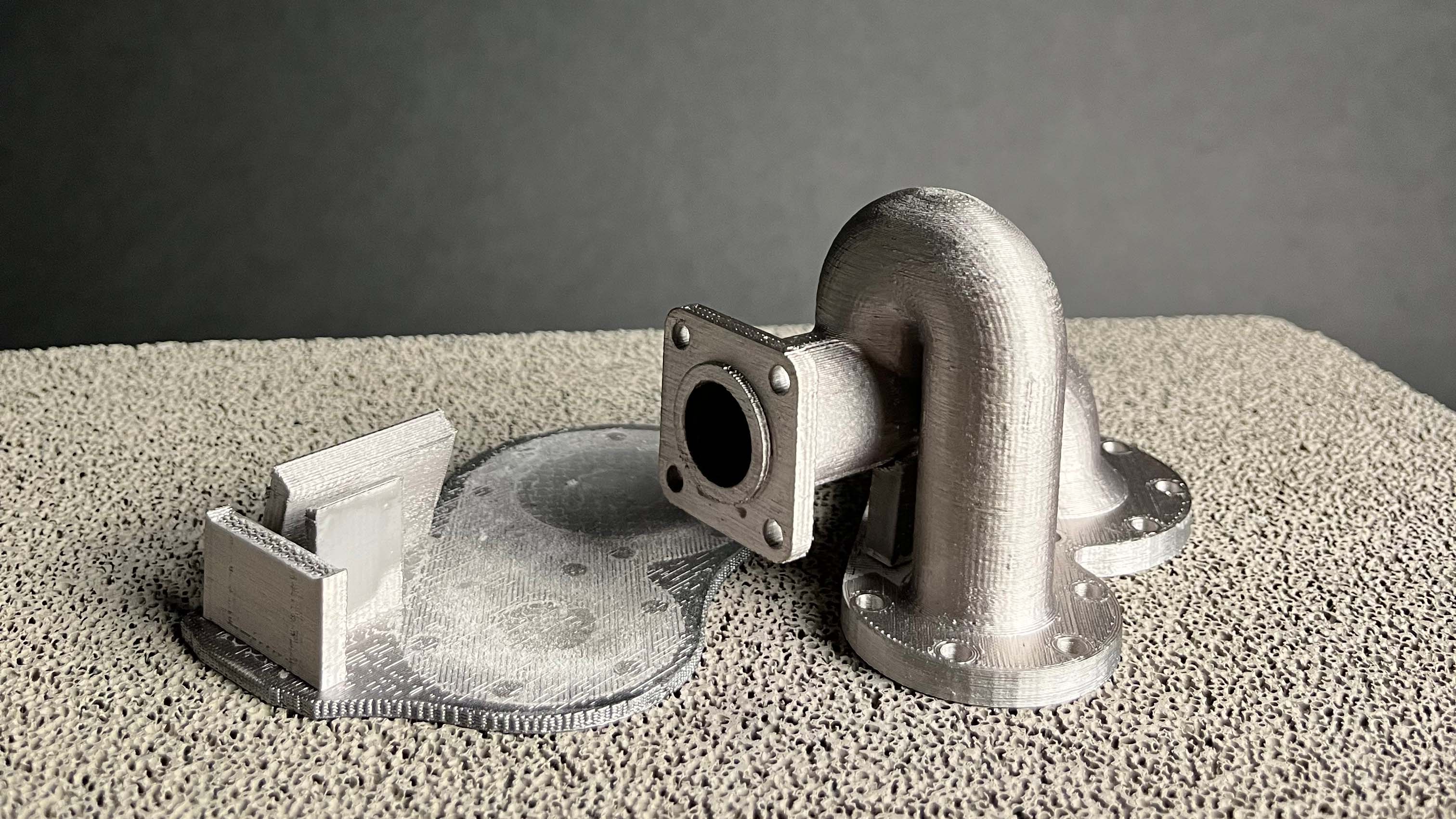

Sintering a part involves heating it to a temperature just under its melting point, at which point the adjacent particles the part is composed of will coalesce into a continuous material. Slowly heating the materials to the sintering temperature allows the polymers in them to first evaporate away. The metal, which contains only a small amount of polymer, is left as pure metal particles. Being composed mainly of polymer, the majority of the support material burns away, leaving only a residual powder designed to keep adjacent pieces of the metal part from sintering together. At the sintering temperature the metal becomes soft like warm modelling clay and shrinks as the free space between adjacent particles all over the part collapses.

Cooling:

When the furnace cools, the part emerges as solid metal, ready for any finishing procedures and end use.